Characteristics of chromite sand:

1. Chromite sand has good resistance to alkaline slag and does not react with compounds, etc.; therefore, in specific applications, chromite sand can prevent thermochemical slag inclusion;

2. In the casting process of condensed metal materials, chromite sand undergoes solid phase calcination, which prevents the infiltration of condensed metal materials, thereby preventing mechanical slag inclusion;

3. The thermal conductivity of chromite sand is several times greater than that of silica sand, which can significantly increase the cooling rate of castings. Therefore, chromite sand can play the role of external chiller in specific applications;

4. High refractoriness, low linear shrinkage coefficient, no reaction with hydroxides, can effectively prevent welding defects such as veining and sand inclusions in castings.

5. Adding an appropriate amount of chromite sand to the mold sand can be used to configure the surface sand of cast steel parts and pig iron. Adding an appropriate amount of chromite sand to the mixture can effectively prevent thermal deformation welding defects.

Production process of chromite sand:

1. The chromite raw material (which has been crushed into powder in South Africa) is washed and processed to screen the particle size with a drum screen to remove mud and impurities;

2. The raw material is dried to remove moisture;

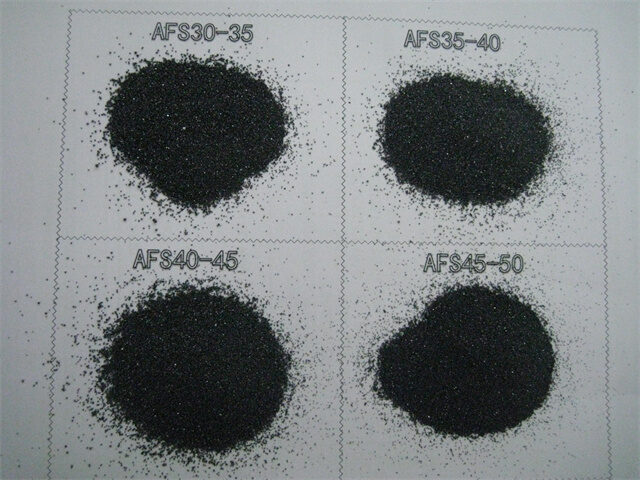

3. The dried raw material enters the vibrating screen to screen the particle size required by the customer;

4. The screened particle size is magnetically separated to remove iron and silicon; the chromium content after magnetic separation reaches more than 46%, and the silicon content is less than 1%;

5. The finished product is packaged.